- Uses profiles in aluminum, wood-aluminum, PVC, steel, light alloys

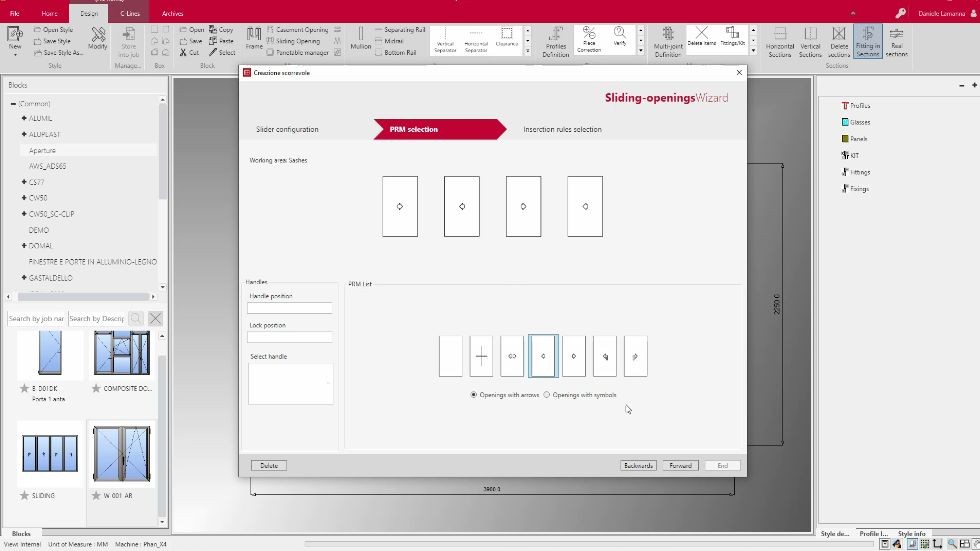

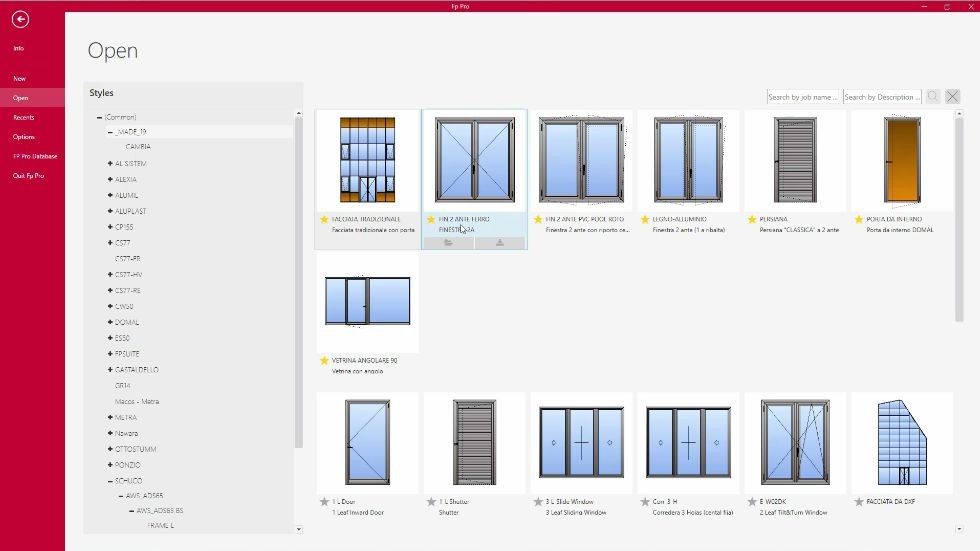

- Handles casements, sliding windows, shutters, sliding-folding doors, window assembly and curtain walls (through the additional FP FACADE module).

- Designs rectangular styles, arched styles and styles with intermediate angles.

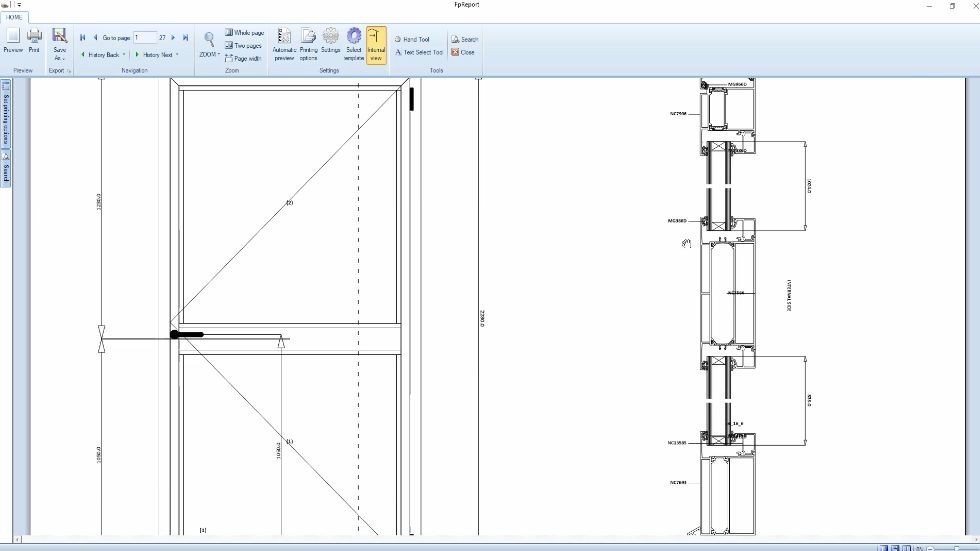

- Graphically presents, in DXF format, dimensioned profiles, multi-joints and sections. 3D display of the styles with real colors and dimensions.

- Manages machining operations with the EASYMAC system to assign fittings to the machining operations defined with FP CAM/CAMPLUS.

Design

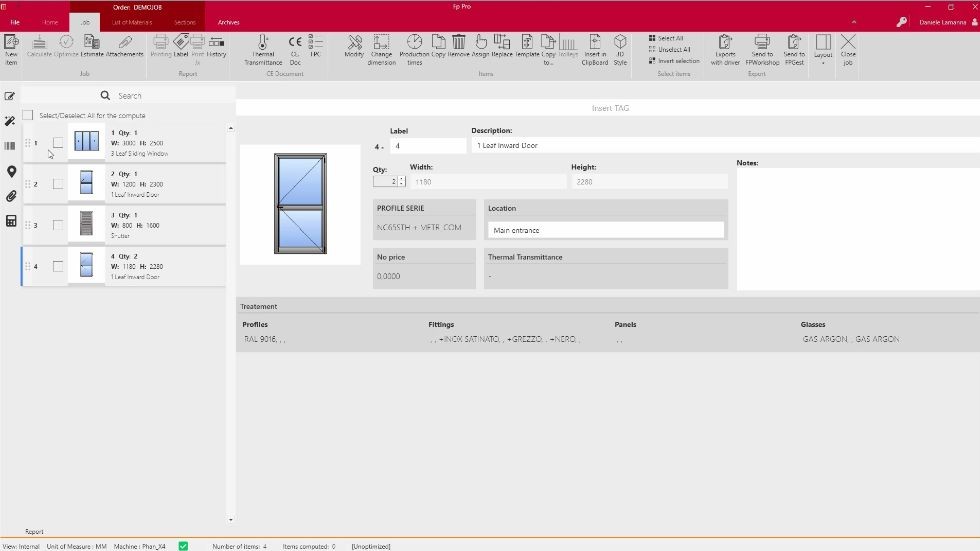

Job definition and calculation

- Guides entry of styles into the job.

- Calculates the materials lists for profiles, fittings, glazing, panels.

- Optimizes bars, short bars and multi-bar management and search for the ideal bar length.

- Connects to FP OPTI2D to optimize glazing and panels.

- Connects to FP GEST to handle production.

Calculation of thermal transmittance and management of CE marking

- Calculates the thermal transmittance with differentiated values for each combination of profiles.

- Defines the Declaration of Performance and the CE label, indicating the initial type tests (ITT) executed.

- Defines the factory production control (FPC) plan, listing the checks which may be customized by the type and organized by the phase of production.

Analytical estimate and calculation of lists

- Manages the costs for materials, processing times, general expenses.

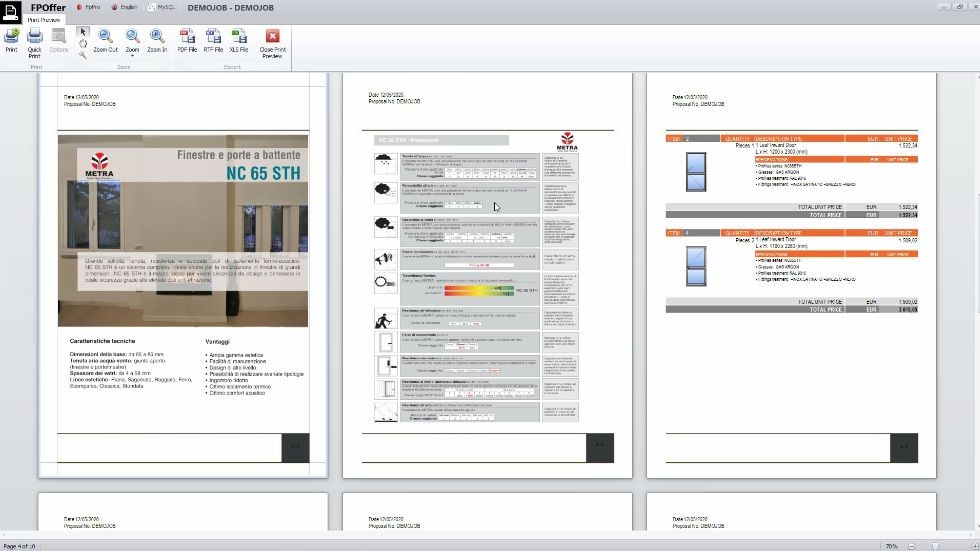

- Calculates analytical estimates for projects producing user-customizable printouts.

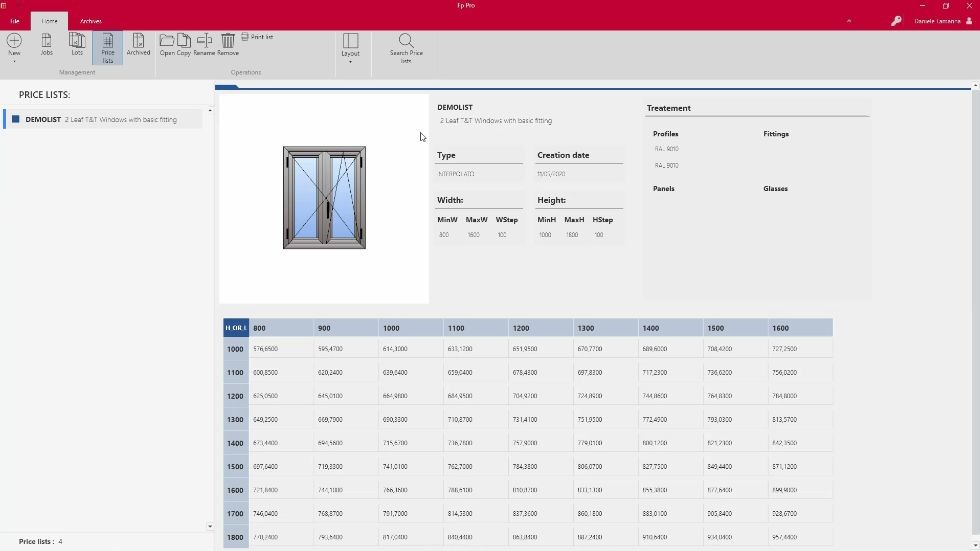

- Calculates the price grid and connects to FP DEALER to process and use the sales lists.

Work lists for the workshop

- Generates cutting lists for the cutting-off machines.

- Generates work lists for the machining centers and welding/corner cleaning machines.

- Trolley management for workpieces and frames.

- Generates support information for the workshops.

Designs rectangular doors/windows, calculates materials lists, performs analytical estimates, generates cutting lists, calculates the heat transmission, manages CE labeling.

Designs rectangular doors/windows, calculates materials lists, performs analytical estimates, generates cutting lists, calculates the heat transmission, manages CE labeling.

In addition to the features of START: designs doors/windows with intermediate angles, connects to cutting-off machines.

In addition to the features of START: designs doors/windows with intermediate angles, connects to cutting-off machines.

In addition to the features of LT: designs arched doors/windows, displays 3D styles, operates in a network, handles job batches, lists, connects to FP WORKSHOP, connects to CAD.

In addition to the features of LT: designs arched doors/windows, displays 3D styles, operates in a network, handles job batches, lists, connects to FP WORKSHOP, connects to CAD.

In addition to the features of STANDARD: manufacturing processes management through EASYMAC, connection to the machining centres for aluminium.

In addition to the features of STANDARD: manufacturing processes management through EASYMAC, connection to the machining centres for aluminium.

In addition to the features of EXECUTIVE: connection to machining centres for PVC, welding machines/trimmer machines, automatic benches for equipment screwing, multi-machine operations management, trestles for workpieces and frames.

In addition to the features of EXECUTIVE: connection to machining centres for PVC, welding machines/trimmer machines, automatic benches for equipment screwing, multi-machine operations management, trestles for workpieces and frames.